LIXIL’s manufacturing plant in Lahr

Innovation meets environmental awareness

Located in Lahr, close to the border to France in the Black Forest, a LIXIL production site deeply rooted in European culture yet open to the latest global trends is a manufacturing powerhouse for the GROHE brand. Since 1956, this site, where more than 750 employees demonstrate their commitment to quality and consumer satisfaction every day, has been an innovator. More than 6 million hand showers, 2 million shower rail sets, and 800,000 shower systems are manufactured for the GROHE brand in Lahr every year.

Known as a center for excellence for the manufacture of showers across LIXIL, this is where almost all of GROHE’s showers marketed around the world are produced. Thanks to the traditional ingenuity and innovative state-of-the-art technology that characterize the Lahr plant, GROHE’s shower systems are favored by consumers who appreciate their consistently high quality and flexible adaptability. Consumer orientation is firmly anchored in LIXIL’s corporate DNA, and meeting consumers’ demands is a top priority at the Lahr plant: The Tempesta series, for instance, is designed for any budget, the SmartControl shower systems offer individual and intuitive water experiences, and Sense Guard, a smart home solution, automatically shuts off the water supply in the event of a pipe burst.

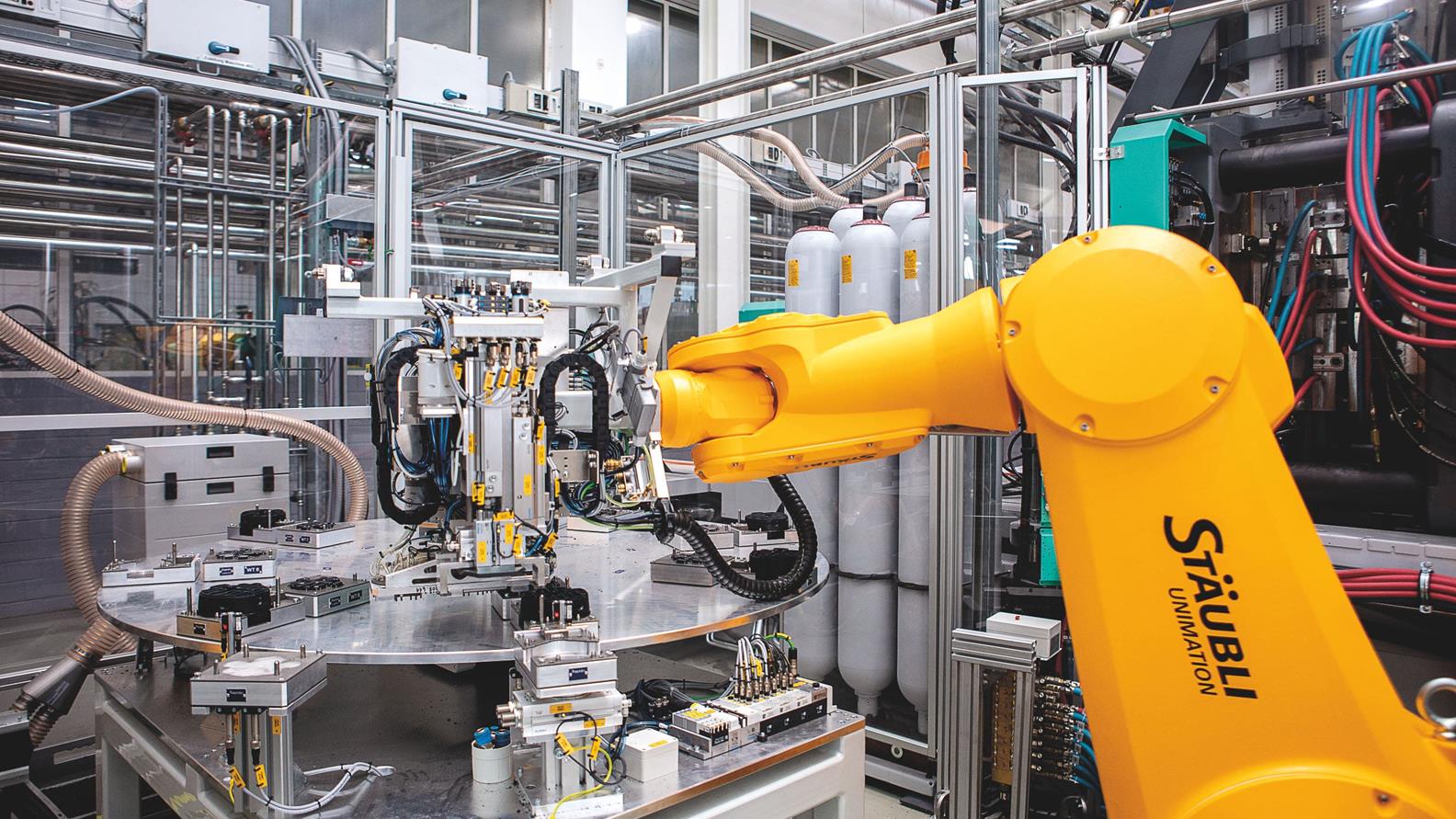

The technological focus of the Lahr production site is on innovative core technologies such as plastic overmolding, and there is a consistent spotlight on the development of innovations. In the implementation of all processes, LIXIL, as it does at other production sites, emphasizes environmentally friendly production. In 2016, a combined heat and power station was put into operation at the Lahr site. It ensures that a total of 2,500 tonnes of CO 2 can be saved per year. GROHE inaugurated its expanded electroplating plant at the Lahr site in 2017 and introduced PVD technology, which produces no waste, in 2019, thereby further increasing the tremendous level of in-house production at the site, while also focusing on sustainability.